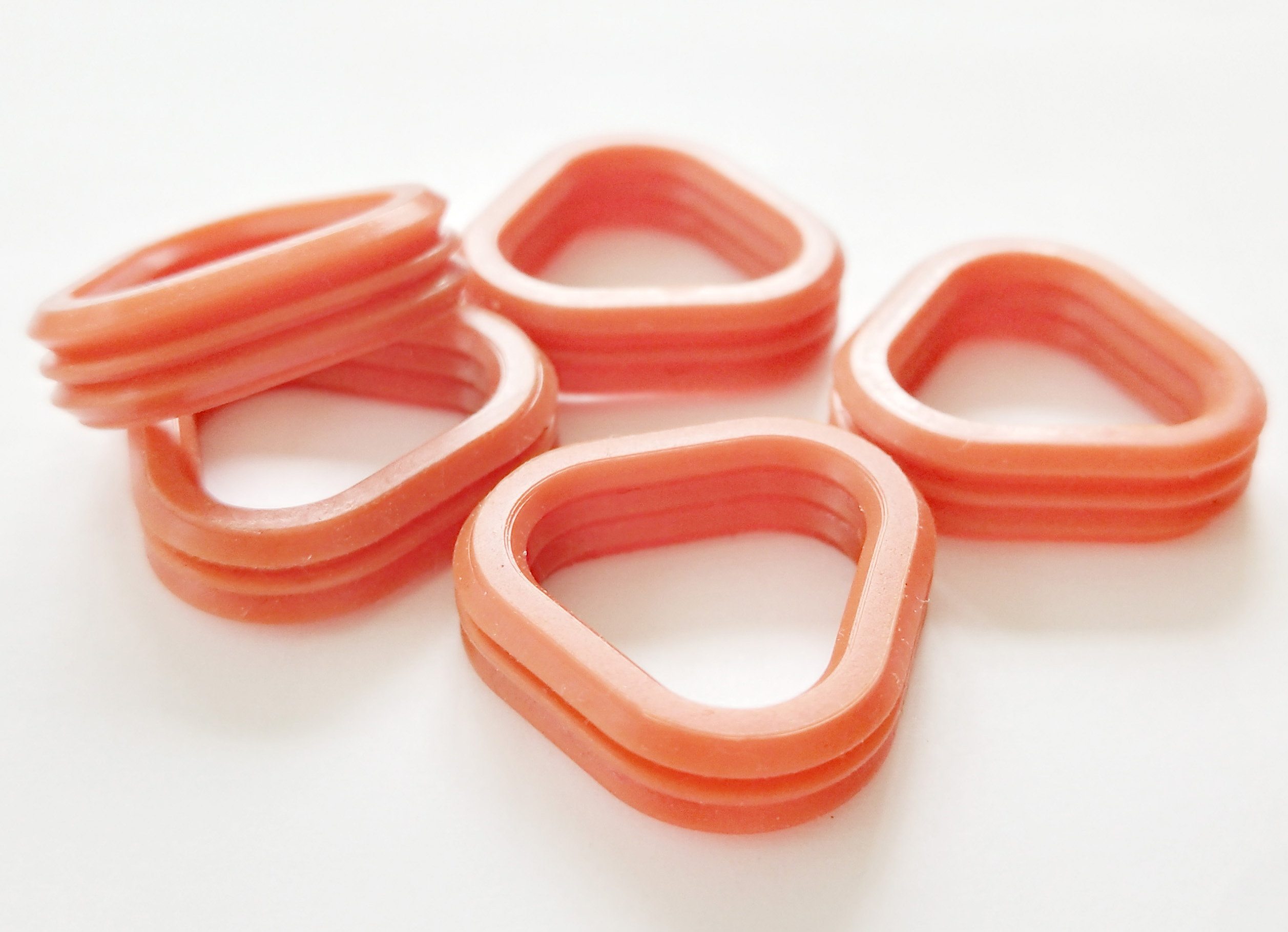

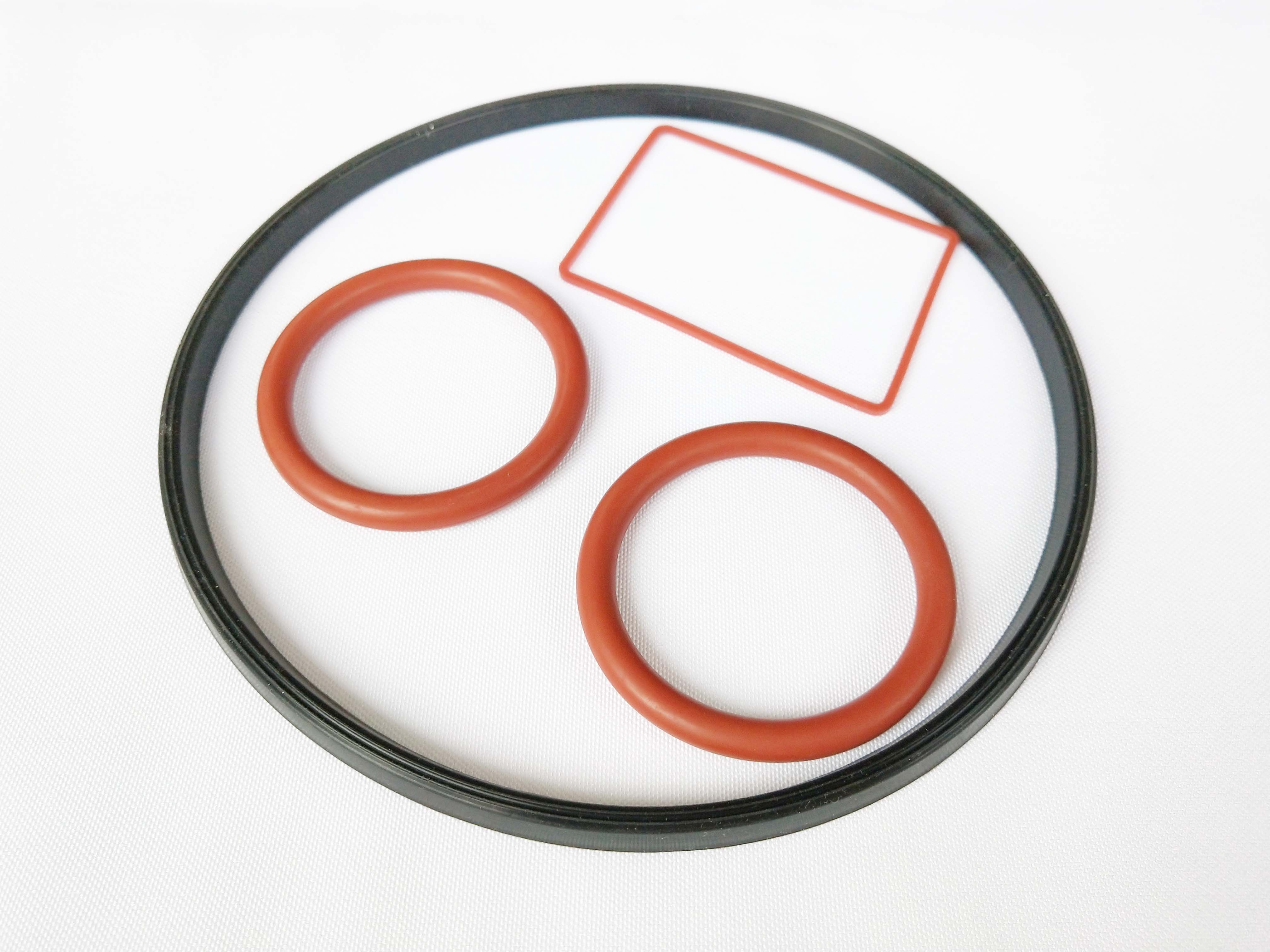

Especially the rubber seals, it normally requests for strict size and appearance control result from its sealing performance, the flash may affect the whole sealing function. Therefore, deflashing process is required after the vulcanization, to remove the superfluous rubber material. This process calls trimming deflashing. Generally speaking, the smaller and more complicated structure, the higher labor cost and longer working time will be taken on deflashing.

Molded rubber sealing parts normally have two ways of deflashing: trim by hand and by machine.

Trimming by hand is the most traditional method. Workers remove the superfluous rubber by knife along the outside of the rubber products. This process requires extremely high proficiency to control the rejection rate. Deflashing by hand does not need high investment, but low efficiency, only suitable for small qty.

Mechanical trimming has two ways, one is grinding by grinding paper and wheel, another is using low temperature frozen method.

Under relative low temperature, rubber will transfer to glassy state from elastomeric state, and become hard and crisp. This hardening and embrittling speed depend on the thickness of the rubber parts. Putting the rubber seals into the frozen trimming machine, under specific low temperature, the thin flash will become hard and crisp because of freezing, but the main rubber part body will maintain relatively elastic. Along with the rotary drum, the rubber parts collide with each other. Rubber parts, pellets, abradant impact and corrode with each other, the trim will be smashed, fall off and finally achieve the target of trimming. Meanwhile, the rubber part will recover its original performance.

Low temperature frozen trimming have good productive efficiency, but does not work well on inside ring trimming.

Another method is grinding by grinding paper and wheel. Put the vulcanized rubber o-ring in the suitable size of grinding bar, and rotate it by electrical machine. And for the outside, using grinding paper or wheel to frict out the flash. This method is more convenience, and higher efficient than handwork, very suitable for the product with small size but big batch. The defect is that the trimming precision is not very high and the surface is relatively rough by grinding.

It will be better to base on different rubber products and orders to choose suitable way of delashing, so as to produce qualified products with better production efficiency and reduce the defective rate at the same time.